OPS & TRAINING

What keeps our ships sailing

07 Jan 2021

It takes courage to go into battle. But you can’t get far without weapons, rations and reinforcements. The Naval Logistics Command (NALCOM) forms the backbone of the Republic of Singapore Navy (RSN), providing engineering and logistics support to ensure its ships stay fighting fit.

The formation began as the Maritime Maintenance Base in 1967, with just about 50 officers and men. When the RSN was inaugurated in 1975, the need for a central agency to coordinate logistics support was clear.

NALCOM was soon formed on 1 Jan 1986, to support the RSN's rapid growth of capabilities in both its ship and shore installations.

Today, it remains key to maintaining the Navy's sharp edge. As the formation celebrates its 35th anniversary this year, here's a look at how its people help keep the RSN "Prepared and Ready".

Propel and preserve

The call came around 11.30pm: the gearbox temperature was too high, affecting the ship's engine.

As the Littoral Mission Vessel (LMV) returned to base, the NALCOM crew on standby sprang into action.

"In that time, we came up with a plan to diagnose the issue. We took out the LMV engineering blueprints to see what could be the possible causes, and delegated who would check what," recalled Military Expert (ME) 2 Jegatheswaran "Jega" s/o Jayagumar, a Senior Assistant Engineer.

He and his team of three provide engineering support to the Navy's Maritime Security Task Force (MSTF), which means being ready to answer to the ships' calls 24/7.

By the time the ship came alongside the wharf around 1.30am, his team was well prepared. They split up tasks and rectified the issue within two hours.

The LMV was able to return to sail, resuming its night watch in patrolling the Singapore Strait.

ME2 Jega and his team are part of NALCOM's Force Readiness Squadron, which provides engineering support to ships. This ranges from pre-mission planning and checks to defect rectifications.

It is no easy task. As their team looks after the RSN's new fleet of eight LMVs, they may face defects they had not encountered before, shared ME2 Jega, 33.

For example, one of the LMVs was having issues with the diesel generator that powers its electrical systems. Over two days, the team dismantled the ship's generator to pinpoint the root cause, and rectified the issue.

For ME2 Jega, the effort is worthwhile once he sees the ship delivered in battle-ready condition to the squadron.

"The ship crew sail for days without seeing their family. So every time they come to us, we try to solve the problem as fast as possible. They depend on us and have that trust in us, so we must fulfil that trust."

Pre-empt and prevent

Just as cars have to be serviced regularly, ships and submarines make periodic visits to their "mechanic" at the shipyard.

While the Force Readiness Squadron deals with corrective maintenance, it is the Force Generation Squadron's (FGS') role to conduct such preventive maintenance.

The RSN's Mine Countermeasure Vessels (MCMVs), for instance, go through regular planned maintenance.

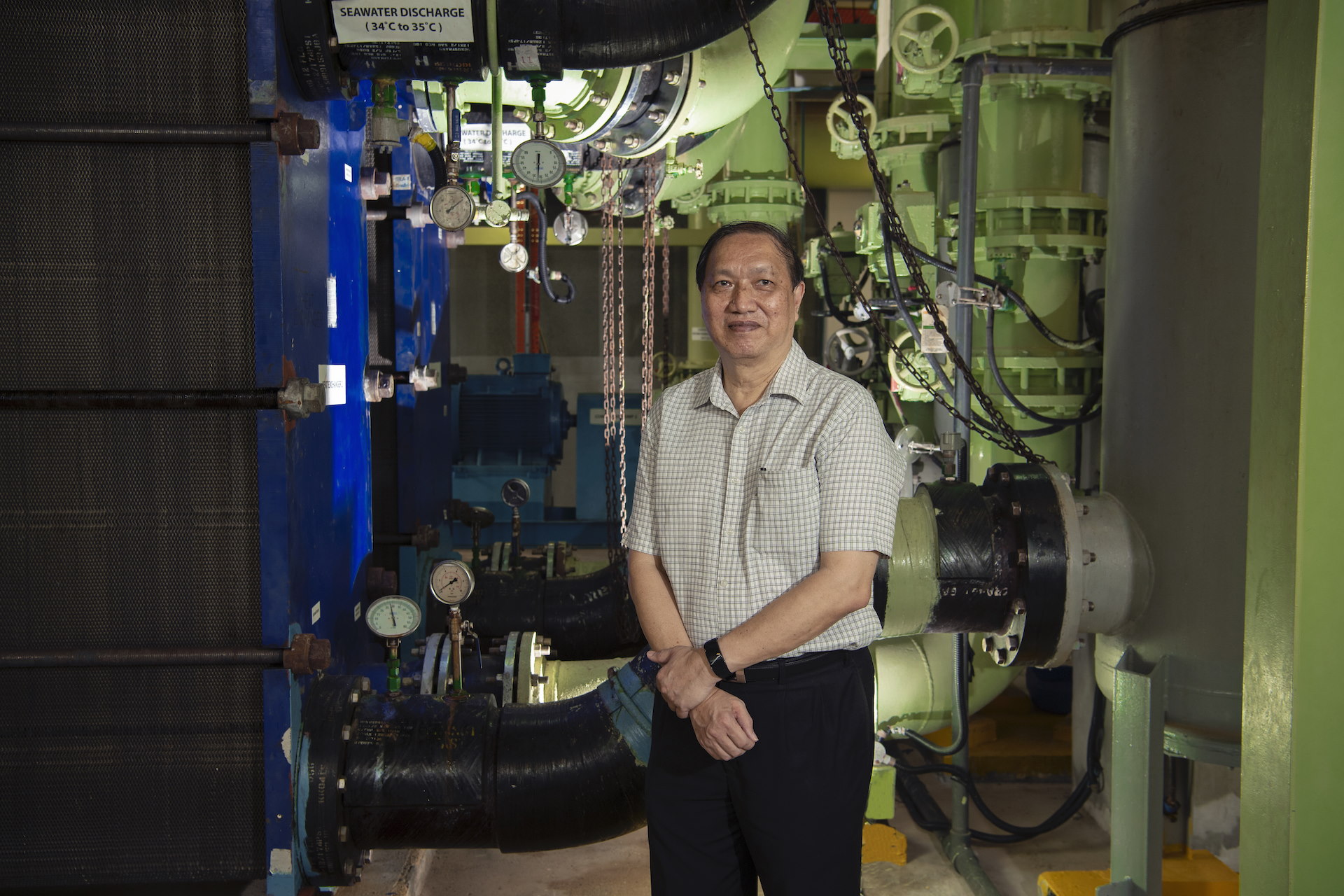

MCMV Lead Superintendent ME3 Cheung Siew Keong and his team come up with the maintenance plans before working with their Singapore Technologies Engineering – Marine Limited (STEML) counterparts to carry out the maintenance works.

They then conduct acceptance tests to ensure the ship and its machineries are in top working condition.

ME3 Cheung, 47 - known as "Papa Cheung" for being a fatherly figure - recounted his experience five years ago, when he sailed out for a sea trial on a Missile Corvette and the ship experienced a mechanical defect.

The crew reacted quickly to emergency drills and the FGS engineers on board managed to fix the defect within 10 minutes.

"This instance really showed the importance of being alert and responding rapidly to an emergency situation. At the same time, I witnessed our people demonstrating their skills effectively, and the ship's officers acting quickly to lead the crew out of a potentially hazardous situation," said ME3 Cheung.

Apart from ensuring a stream of well-maintained Navy ships, NALCOM leverages on Civil Resource vessels for support during national emergencies.

Said Ms Hor Ping Yin, an Assistant Manager in the FGS' Civil Resource Generation Centre: "These vessels supplement our Navy platforms to act as a force multiplier."

Smaller vessels like tugboats, for example, can be enlisted into service to provide critical towing services during emergencies, while larger merchant vessels can be used to support training and humanitarian operations.

Plan and prepare

An important part of naval logistics is optimising the management of resources to ensure that ships are ready for deployment and to sustain out at sea.

Taking up that role is the integrated Operational Logistics Centre (iOLC) within NALCOM's Headquarters, or HQ NALCOM.

"We are the single entity that talks to the fighting formations with all the deployed ships," said ME5 Soh Teck Soon, Section Head of iOLC's Mission Readiness Support Section.

"My team is plugged into the fleet's mission planning, so we have first-hand understanding of their operational demands...We then work with the engineering centres in NALCOM to develop a support plan," added the 41-year-old.

This plan includes system checks to be done; engineering spares and general supplies to be loaded; the deployment of engineers; and even contingency plans of sending spares and manpower to foreign ports to support RSN ships arriving there.

"We see to the ship's needs throughout its deployment, from the planning stage to the ship's return. Every time the ship is out, we will keep a watchful eye," he said.

At the other side of the house is ME3 Lilian Tan, Senior Supervisor Logistics in HQ NALCOM's Logistics branch. The 48-year-old keeps NALCOM's payments and requisitions in check, as the formation supports the rest of the Navy in raising purchase requests.

Most recently, she was involved in supporting the fight against COVID-19, through setting up isolation bunks for RSN personnel who had to be isolated in camp before and during their duties, over the circuit breaker period.

She and her team had the task of setting up accommodations for more than 200 personnel at Clementi Camp – with just two days of planning.

"It was challenging. A lot of suppliers were facing manpower constraints then and unable to make the delivery," explained ME3 Tan.

"However, I engaged my Army peers for their support and was able to leverage my supply knowledge and past experiences so that we managed to get everything we needed," she added.

"It was tiring as we had to work long hours, but when I saw our RSN personnel smiling and thanking us, I knew I had done my best to support them."

Provide and "pamper"

Ships need fuel; engineers need tools and spares; and servicemen need food and water. Managing the entire inventory and base facilities for the RSN is NALCOM's Force Support Squadron (FSS).

It takes care of provisioning and inventory management – from planning what to buy, when to buy it, and how much to buy, to its storage and delivery.

The FSS also runs the naval bases like a town council, maintaining the facilities and overseeing shuttle bus services and cookhouse meals to ensure that base operations run smoothly.

Mr David Chan, FSS' Head of Operations, has served in the RSN even before NALCOM was formed, starting as a Maintenance Base Technician in 1977.

While demand on logistics has increased over the years, so has NALCOM grown from strength to strength, said the 61-year-old.

"The provisioning of spares to support maintenance and operations isn't straight-forward - you can't just say you want something and it arrives at your doorstep the following day.

"We have to think through and plan for inventory and provisions, freight forwarding, and distribution. This is what NALCOM does in orchestrating the whole supply process chain."

Reflecting on the formation's transformation, ME7 Khoo Koh Giok, Commander NALCOM, noted: "As the Navy operates in a more complex and volatile security environment, NALCOM's role of ensuring the readiness of our ships and naval bases is more important than ever.

"With our people's deep domain expertise, strong fighting spirit and professionalism, I am confident that NALCOM will continue to grow stronger and deliver mission success to the RSN."

Among the full-time national servicemen in FSS is Lance Corporal (LCP) Philip Poon from the Materiel Support Centre, who maintains and delivers ammunitions for the Navy.

The 21-year-old Munition Support Assistant recalled his first operation, where he had to forklift and deliver missiles to a ship, taking the entire day.

"It was a long time because we had to execute the lifting carefully so as not to damage the frame of the missile. We had to keep focused throughout, which wasn’t easy, and I felt very accomplished after that."

LCP Poon also supported the Rim of the Pacific exercise, or RIMPAC, last year, delivering Aster missiles to frigate RSS Supreme.

On how his behind-the-scenes work contributes to mission success, the full-time national serviceman said: "If (the ship) isn't able to smoothly or safely receive the missiles, their firing may not be successful.

"I think it's just like a relay race; we're just passing the baton to them and no matter which one of the runners finishes the race, we're all equally important."

ALSO READ IN OPS & TRAINING

New firing range complex at Bedok Camp; Medical Classification System to be redesigned

27 Feb 2026

To train soldiers for a more complex environment, the SAF will build a new Multi-Mission Range Complex, as well as introduce opportunities for national servicemen to take on new roles, and more ways to volunteer.

Reaffirming their commitment to defence

07 Feb 2026

Over 3,000 NSmen displayed their commitment to Singapore’s defence at a MOBEX in Selarang Camp.

First in, last out at Ex Wallaby 2025

06 Nov 2025

Meet the teams who toil behind the scenes to enable the smooth conduct of the SAF’s biggest unilateral overseas exercise.