TECH ALCHEMY

PHOTO // Kenneth Lin & Courtesy of Singapore Army & Republic of Singapore Navy

Some say that we are living in a golden age of technology; from the computing power found in today's mobile phones to the smart electronic locks in homes that keep intruders out, the reach and utility of technology are pervasive.

So why should it be any different for soldiers? As a tiny nation, Singapore has more reason than most to look to technology, in order to multiply its forces and to see further and respond quicker than others can.

And that is where defence engineers and scientists come in: to dream up next-generation systems that will let tomorrow's soldiers fight better and smarter.

From buying and customising technology to suit the Singapore Armed Forces' (SAF's) needs to building complete fighting systems from scratch, they are the de facto fourth Service of the SAF.

Find out how they use their collective brainpower to keep Singapore safe.

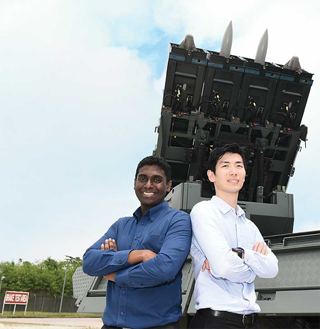

SKY SENTINEL If Singaporeans knew what it takes to protect the skies right over their heads, it would blow their minds. For the past decade, engineers from the Defence Science and Technology Agency (DSTA) have been working with the SAF to build an island-wide air defence shield that stands ready 24/7. A complex web of skyward sensors, weapon systems and command nodes, the Island Air Defence (IAD) System spans across Singapore. By networking existing and new systems, it enhances the Republic of Singapore Air Force's (RSAF's) air defence capabilities. "It allows everyone to be on one common air situation picture. This allows us to orchestrate the air battle more effectively and with shorter response times," said Colonel Koh Ee Wen, Commander Air Defence Group. Spinning the web The IAD System draws its power from an entire suite of weapon and sensor systems. These include the G550 Airborne Early Warning aircraft, the SPYDER short-range Ground-Based Air Defence (GBAD) weapon, the various Unmanned Aerial Vehicles of the SAF and the Aster-30 Missile System (not fielded yet.) It was in 2006 that a team from DSTA began drawing up plans for the IAD System. The team quickly realised that there were no similar air defence systems in the world they could take reference from. Most other countries simply do not require such a tightly integrated and networked system -- their vast land masses mean that their air defence systems are scattered to cover just key geographical areas. "The benefit of having something like the IAD System means that the RSAF can pool all the resources of the weapons, sensors and Command and Control (C2) systems to provide comprehensive air cover for the whole of Singapore," said Mr Tan Bing Wen, Project Manager (Networked Systems), DSTA. Besides conducting extensive studies to make sure that the system would be effective, the IAD team designed it in a way that allowed it to be constantly refined. Being able to integrate with the best systems from around the world was crucial for it to respond quickly to changing needs. It also needed to be compatible with other systems such as the C2 network as well as weapons and sensor systems. The all-seeing skyward defence system was taking shape. Hitting a milestone The networked SPYDER system that came online in 2014 marked a significant milestone for the IAD team. "It was the first time we had acquired and integrated a weapon system so tightly into the IAD System," said Mr Tan, 32. Plugged into the IAD System, the SPYDER could respond faster and with greater precision. With an intercept range of 15km and the ability to engage targets up to 9km in the sky with its state-of-the-art missiles, it was a formidable weapon. Mr Karthikeyan S/O A Sadhananthan, a 27-year-old project engineer from DSTA, said: "To see it working together for the first time, the feeling was indescribably wonderful." But that was only one piece of the puzzle. "As a complex project with many parts and many systems in any one class of systems, we had to look into how these individual systems would 'talk' to each other to make up one coherent IAD System," said Mr Tan. "Fortunately, the RSAF and DSTA worked very closely together. At the end of the day, every one of us is working to deliver a networked air defence capability for the country." The team continues to develop and deliver the rest of the IAD System.

TECH HIGHLIGHTS Over the years, DSTA and DSO have procured and built many innovations for the SAF. 1) High Mobility Artillery Rocket System This heavy-hitting artillery platform can strike targets up to 70km away with its advanced rockets and needs only about 20 seconds for an experienced crew to get to a ready-to-fire mode. To strengthen the system's command and control capabilities of the Lockheed Martin platform, a DSTA team developed and integrated a Battlefield Management System that links it to other units for swifter response times. 2) Multi-Mission Range Complex This first-of-its-kind indoor shooting range complex allows soldiers to train even in bad weather and can be configured for both day and night shoots. DSTA incorporated several innovative features in the complex, such as movable partition walls and electronic targets that allow for various settings so that soldiers can train to fight in different urban scenarios. 3) Integrated Geographic Information System DSO and DSTA developed a system that improved the SAF's capacity to process and disseminate geographic information in a timely and optimal manner.

Building a ship When the Republic of Singapore Navy (RSN)needed a new ship to replace its ageing Patrol Vessels, it called on DSTA to develop what is now known as the Littoral Mission Vessel (LMV). "Instead of acquiring a new ship off-the-shelf, we decided to design a vessel from scratch. By doing so, we could have a ship that was tailored to the RSN's needs," said Lieutenant Colonel (LTC) Chew Chun Chau, who heads the LMV Project Office, RSN. The 80m vessel is described as being smarter, faster and sharper than its predecessor. The LMV houses an Integrated Command Centre (ICC), is capable of speeds of over 27 knots, and carries sophisticated weapons and sensors. It is also designed to be more cost-effective to build and maintain. Three in one To achieve the lean manning crew size of 23 (a Patrol Vessel needs a 30-strong crew), DSTA came up with the novel idea of integrating the three traditional main operating areas of a ship -- the Bridge, the Combat Information Centre, and the Machinery Control Room. It was not an idea hatched out of the blue, said Ms Tessa Gan, a Project Manager for the LMV programme from DSTA. The team spent many hours in simulation laboratories, putting sailors through realistic models of the ICC. The purpose-built simulation facility came with a 360-view out of the LMV windows. This allowed RSN sailors to try out new ways of operating the ship. Other technologies, such as a stern ramp system that would allow faster launch and recovery of small boats, were also added. Naval ships usually use shipboard cranes to raise and lower small boats. The LMV was also designed so that it could be quickly reconfigured for different missions. For example, it can be configured so that rigid-hull boats, boarding teams and a helicopter can be embarked for maritime security operations. A mobile medical facility can also be placed on the LMV to provide medical coverage and support during search and rescue operations. Putting it all together The LMV is a vessel that contains hundreds of thousands of individual parts, all pieced together to form a coherent whole. "Just to get the ship to float and move requires about 50 different systems working together," said Ms Gan, 42. Even for something as ubiquitous as power supply, there are three different voltages of electrical power to "feed" all the systems on board. "That's why we work very closely with the shipyard to make sure that all the pieces are put together properly and on schedule," she added. Asked how it felt to stand in the ship that she helped bring to reality, Ms Gan said: "To say that I feel satisfaction would be an understatement. To see it finally 'in the flesh' as it was intended, the feeling of pride and joy is immeasurable." A fleet of eight LMVs will be built. Three have been launched and the entire fleet is expected to be fully operational by 2020. Greater minds Singapore's defence technology community, which marks its 50th year this year, includes DSTA, DSO National Laboratories, and the Future Systems and Technology Directorate (FSTD). Their work spans a wide range of disciplines and looks into many areas of interest, but they all work to ensure Singapore's peace and security. While DSO focuses on research and development of technologies in areas where the SAF has limited acquisition options, DSTA develops, acquires and integrates defence equipment and systems for the SAF. These two organisations work with the FSTD, which develops game-changing concepts and disruptive technologies to deliver cutting-edge capabilities for the SAF. "The FSTD is on a constant lookout for new and emerging technologies and solutions that can overcome challenges that the SAF faces," said Mr Lim Teow Hoe, Deputy Future Systems and Technology Architect. For example, the FSTD has identified robotics, big data analytics and cyber security as some key areas to look into for the future.

Mapping Singapore's critical nodes National security is not just about putting the flashiest new gear into soldiers' hands. At the back end, it also requires careful study to identify areas of weakness and interdependency. For example, if power was lost in certain parts of Singapore, how would telecommunications and other essential services be affected? Short of deliberately doing it for real, there is no sure way to find out. For example, when Hurricane Sandy hit the United States in 2012, it caused widespread power failures that, in turn, affected transport and other infrastructural systems. If something similar happened in Singapore, how would the country be affected? How it works That was the question that the National Security Coordination Secretariat (NSCS) wanted answered. In November 2012, the NSCS programme on Inter-Dependency Assessments and Studies (NIDAS) was set up in DSO National Laboratories to model and identify links in Singapore's critical infrastructures. The NIDAS platform offers a comprehensive and coherent view of Singapore's critical infrastructures by analysing links between the energy grid and other networks such as water resources and info communications. "In a nutshell, it's a web of nodes (which represent the physical and cyber infrastructures) and links (which identify what other systems they are connected to, and why or how). "Within that, there are also other models that calculate and put together outcomes based on the parameters we input," said DSO scientist Ng Fu Xing. Assembling the puzzle The complexity of the model mirrors Singapore's infrastructure. While researching for NIDAS, the team had to visit various sites and infrastructural installations. "We had to literally climb above them and even under them, just to see how they work," said Mr Toh Kaiyang, a senior scientist from DSO. After the ground research, the team would return to their laboratory and codify each of these uncovered links into mathematical models. "Once we piece together each of the links, what we end up with is a model that can tell us what would happen to certain nodes if certain links were broken," said Mr Toh, 34. "It was like Singapore's greatest and biggest jigsaw puzzle! What we did was to piece these things together and make sense of it all." The project is still ongoing as the team works to enhance the information in the platform. "The thing we realised is that, in Singapore, things are always constantly changing," said Mr Ng. "There are a lot of hidden links and it's satisfying to be able to put all of that together into a platform that benefits the safety and security of Singapore."

Space View Did you know that Singapore is among the handful of nations which are able to design and build successful space-going satellites? In December 2015, Singapore put six satellites into orbit in a launch from the Satish Dhawan Space Centre located north of Chennai in India. The heaviest of the lot was the 400kg TeLEOS-1 satellite, designed and built by ST Electronics (Satellite Systems). Satellite Systems is a joint venture between ST Electronics, Nanyang Technological University and DSO. The TeLEOS-1 satellite covers major shipping, disaster and fire-prone regions with a revisit time of 12 to 16 hours per day (that means it passes over the same spot on Earth once every 12 to 16 hours). Lift-off It was no easy task to design a 400kg system filled with delicate electronics capable of transmitting data hundreds of thousands of kilometres back to Earth and yet could withstand the stresses of being blasted into space. To break free of Earth's gravity, a speed of more than 7km per second is needed. Recalling the day of the launch, DSO chief engineer Koh Wee Eng said: "I was quite nervous (at the ground control station located in Singapore). Thank goodness the satellite ejected successfully! "Then the signals started coming in, and the nervousness turned into happiness." The build The team took about five years to design and build the TeLEOS-1. "We went from a clean sheet to a full-flight model orbiting in space in five years," said Mr Koh, 56. It helped that some of the team members had come from the development of the 105kg X-Sat, a microsatellite designed for academic research, but the team was largely in unfamiliar waters. It was not a matter of simply buying parts and assembling them together, added Mr Koh. The team had to design, build and integrate the parts into a working satellite that could survive the unique conditions of space. Adapting tech "Our engineers had to be smart to adapt what they learnt for our satellite," shared Mr Koh. That meant putting in the elbow grease to debug the systems and solving problems along the way. "We just hunkered down and did the work," he said, recalling the many times the team worked into the wee hours. "But seeing the satellite launch and start working, no words can describe the satisfaction. "After all, only a very small percentage of the world's population can say they built something that went to space!" Bulletproof recipe Imagine a thin piece of see-through material tough enough to stop bullets. That is what researchers at DSO have cooked up - except that the material is not glass, but ceramic. Forged by a process that involves compacting microscopic grains of ceramic powder and heat treatment over and over again, the production of DSO's transparent ceramic armour is akin to developing a precise and sophisticated baking recipe. The results are astounding; lighter and stronger than conventional armoured glass, a piece of ceramic material less than 1cm thick is all it takes to stop an armour-piercing round. Perfecting the mix To create the clear material from ceramic, which is usually opaque, the team experimented with the compaction and heat treatment process before finding the right mix. "It is notoriously difficult, and only a handful of groups (around the world) have achieved this," said DSO researcher Ang Seok Kim, 41. The material begins life as an off-white ceramic powder. The challenge is in compacting the grains together uniformly to make sure there are no air gaps in the pane of material. Stopping bullets The secret to its arresting properties is in the structure of the material. Unlike traditional armoured glass that stops bullets by sheer mass, the ceramic pane actually shreds the bullet as it drives into the material. "Ceramic is a very hard material, so what happens as the bullet hits the material is that it is being 'cut' and it disintegrates. It also loses velocity in the process to eventually come to a stop," explained Mr Earnest Lau, a researcher and Lab Head (Advanced Materials) at DSO. The first time that the team saw the stopping power of the ceramic material during a ballistics test, they were amazed. "We didn't expect it to work so well, since it was such a thin layer," said Mr Lau, 44. For a conventional piece of armoured glass to achieve the same stopping power, the thickness would have to be from 6 to 10cm, a few times thicker than the ceramic material. Scaling up Having proved the effectiveness of their material, the duo then started to think of scaling the process for commercial mass production. To replicate what they achieved in the lab was not simply a matter of scaling the equipment up. "Workers need to be trained and the workflow for the manufacturing process needs to be worked out in order to make an economically-viable product. It's not a trivial process," explained Ms Ang. While development of the material under lab conditions took about two years, starting from 2013, the manufacturing process is still under development. The team expects the product to be commercially available in another two years. So far, apart from obvious applications such as in the windows of military vehicles and protection of high-value assets, the team thinks that the product could also see commercial success in civilian applications such as protective casings for expensive lenses. Clearly, the opportunities are boundless. Story by Tan Jun An The past, present and future of defence Ever wondered how military weapons and equipment are created? Out in late November, this four-part Web series on youtube.com/cyberpioneerTV aims to satisfy your curiosity by going behind the scenes to showcase Singapore's defence scientists and engineers at work. Each episode has a different theme and the series will explore various aspects of the Defence Technology Community (DTC) to inspire current and future generations to build a stronger Singapore Armed Forces. The first episode reviews past innovations made by the DTC, and how they have always been pushing limits to achieve technological advances. The second episode explores how defence scientists and engineers from both public and private institutes work closely together to accomplish the challenging task of staying on the cutting-edge of defence. Think defence science cannot be applied during peacetime? Think again! In the third video, the series looks at the chemical and biological defence laboratories which are built to identify virus strains during outbreaks and to speed up the creation of cures. And of course, going into the future, Singapore will need a larger talent pool of defence scientists and engineers. The last episode introduces some of the programmes which are already in place to help nurture the talents needed for a stable and secure Singapore. |