TECHNOLOGY

MASTERS OF INNOVATION

22 Jul 2010

Meet three bright sparks of this year's PRoductivity & Innovation in Daily Efforts (PRIDE) Day.

"Productivity is never an accident. It is always the result of a commitment to excellence, intelligent planning and focused effort," said Paul J Meyer, a pioneer in personal development. This was the exact spirit showcased at PRIDE Day 2010.

Themed One idea, many possibilities - Innovation begins with you, the Ministry of Defence (MINDEF) PRIDE Day 2010 recognised individuals and Work Improvement Teams (WITs) for their outstanding contributions towards organisational excellence, innovation and productivity. Some of the best projects were showcased at the PRIDE Day exhibition held at Toa Payoh HDB Hub from 8 to 10 Jun.

Introduced in 1981, the PRIDE movement is aimed at promoting a culture of creativity and innovation. In the 2009 financial year, it saved MINDEF a whopping $206.7 million - a 48 percent increase in savings from 2008.

Deputy Prime Minister and Minister for Defence Teo Chee Hean lauded the innovative efforts by MINDEF and Singapore Armed Forces (SAF) personnel on the event's opening day. He said: "While productivity is about enhancing the SAF's mission effectiveness by making sure its people are better organised, trained and equipped, and resources are efficiently used, productivity improvements are possible only when there is the desire in each person to do better."

Chinook Helicopter Infrared Light Detector

Cost avoidance: $147,800 over five years

The ordinary TV remote control was the inspiration behind Military Expert (ME) 2 Ong Chin Lin's Infrared Light Detector. A complaint from his father about a faulty remote control prompted him to research on how remote controls make use of infrared rays. Through his research, he found that photo transistors can detect infrared rays.

The Assistant Engineer from the Air Logistics Group, who services Chinook helicopters, realised that his discovery would be useful at his workplace since infrared rays are emitted by the Chinook's formation lights. These lights help the aircraft stay in formation at night.

His unit, which usually has to borrow night vision goggles to see if the formation lights are working well, was originally planning to purchase their own sets.

Rather than spending $18,500 on a set of night vision goggles, ME2 Ong spent just $25 on his home-made alternative, which is composed of a photo transistor, a circuit board and an LED indicator housed in a PVC pipe.

ME2 Ong said: "There's nothing new in my discovery. But my project shows that there's always something in the ordinary that we can apply to our work."

ME2 Ong said: "There's nothing new in my discovery. But my project shows that there's always something in the ordinary that we can apply to our work."

BEST WITs Project Award

Programmable Pressure-activated Flotation Device

Benefit: Safer training

Most life jackets are either manually inflated or auto-inflate upon contact with water. But what the Commandos needed was something in between.

"We can't use auto-inflatable life jackets because we want to train soldiers in water. But the manual ones were also not ideal in case a soldier is unconscious and is unable to pull the cord on the life jacket," explained 1st Warrant Officer (1WO) Francis Toh, a company 2nd-in-charge from the Special Operations Tactics Centre (SOTAC).

With this in mind, Team Ironman, a WIT from SOTAC, designed a device that allows users to set the depth at which the jacket would auto-inflate.

While it costs $250 apiece and $100 in yearly maintenance, the device promises safety benefits that far outweigh its cost, said 1WO Toh, who is also Team Ironman's leader.

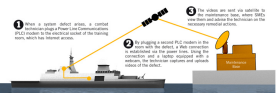

Subject-Matter-Expert (SME) Reachback

Cost savings: approximately $2.2 million per annum

What happens when systems or machines on a Republic of Singapore Navy (RSN) ship malfunction on the high seas? Skilled technicians or SMEs will have to be flown to the nearest harbour to fix the defects, which can take between four and 10 days.

To counter this costly and time-consuming method, a 10-man team from the Changi Maintenance Base, called Rectifier, came up with the idea of using video conferencing to rectify defects.

By tapping into the power lines to extend Local Area Network coverage to different parts of the ship, and using a laptop and webcam, SMEs in the maintenance base are able to look at the defects and advise technicians on board accordingly.

"Now, even if a ship is as far away from Singapore as the United States, we are able to fix defects immediately or within three days...this greatly enhances the operational readiness of our ships," said Rectifier team member ME3 Kee Siew Huang, a communications systems group in-charge.

In May, this project was also shortlisted as one of 32 finalists in an international competition organised by the American Society for Quality - a first for MINDEF.

ALSO READ IN TECHNOLOGY

AI joins the fight in national cyber defence exercise

12 Nov 2025

AI and closer collaboration among agencies and industry are taking centre stage in this year’s Critical Infrastructure Defence Exercise (CIDeX).

They built this city

01 Oct 2025

Turning vision to reality: the team behind SAFTI City clinches the Defence Technology Prize 2025 Team (Engineering) Award!

Operating over skies & seas

22 Aug 2025

This gear is designed to help a Sensor Supervisor survive emergencies in the air and at sea.