TECHNOLOGY

KEEPING DANGER AT BAY

23 Sep 2010

The Wheelbarrow Mark 9 (Mk 9) remote-control vehicle keeps Explosives and Ordnance Disposal (EOD) personnel safe while they protect others from harm.

Few would dispute the pure guts it takes to don a bomb suit and walk into the blast radius of a suspected explosive. Although protected by the suit, EOD personnel still risk life and limb each time they are called to the front line to defuse a potential tragedy.

While there will always be situations where the man in the bomb suit is the best option, Unmanned Ground Systems (UGSes) such as the Wheelbarrow Mk 9 are shouldering more of the risk as technology continues to improve.

Apart from allowing EOD operators to work from a safe distance away, the Wheelbarrow Mk 9 - made by Northrop Grumman subsidiary Remotec - helps to gather information from the danger zone. Operators can use it to see and touch suspicious packages via its on-board array of imaging capabilities and its telescopic arm.

Built to be agile

Most EOD remote-control vehicles are battery-powered to reduce the risk of accidental detonation, and the Wheelbarrow Mk 9 is no exception.

What sets the Wheelbarrow UGS apart is how engineers have placed the battery packs within the vehicle. Housed in the main chassis unit, the batteries can be moved forward or backwards to alter the vehicle's centre of gravity. This design effectively transforms the heaviest (and most suitable) component as a counterweight to enhance the vehicle's capabilities.

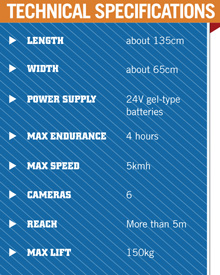

With this feature, the Wheelbarrow Mk 9 can negotiate 45-degree inclines such as staircases, as well as carry and tow heavy objects. Tracks as opposed to wheels plant the vehicle firmly on the ground, enabling it to safely straddle trenches of up to 0.5m wide and mount a 0.2m-high step with ease. The Wheelbarrow Mk 9 can also turn on the spot to negotiate tight confines. Versatile in both urban and open environments, it can easily negotiate doorways, narrow corridors and various types of terrain.

The Wheelbarrow Mk 9 can also carry just about anything an EOD operator needs to anywhere. Removal of small obstacles in its path, towing loads and even delicate movements such as prying open a suspicious package are all possible thanks to the precise actuators controlling each articulation in the manipulator arm.

When the boom of its telescopic arm is fully retracted, it can carry loads of up to 150kg, or the equivalent of two average men. Even when the boom is extended to its near-maximum length at 5.2m, it can still lift up to 5kg. The Wheelbarrow Mk 9 has a maximum reach of more than 6m.

Multi-sensory capabilities

Depending on the mission, the Wheelbarrow Mk 9 can be fitted with a multitude of payloads such as cameras, weapons, detection equipment and manipulators such as grab arms to be fitted at the end of its boom.

At each articulation of the boom sits powerful actuators that provide movement and allow the vehicle's cameras to be pointed around corners and moved closer to objects on the ground.

Videos captured by the Wheelbarrow Mk 9's six cameras provide its operator with an unfettered view of the vehicle's surroundings. High-quality still imagery is also available.

The operator can even talk to casualties and attackers through the UGS' two-way audio capability. This allows for communications to take place without putting additional people in danger.

Control projection

The Wheelbarrow Mk 9 may be controlled via one of three ways: digital radio, cable or fibre optics. Coupled with its control system which boasts a touch-screen interface with the option for a joystick controller, the vehicle is as intuitive to control as it is manoeuvrable.

The digital radio control option allows the vehicle to be remotely controlled from more than a kilometre away, while fibre optics allow control up to 500m away and the cable option can gap distances up to 150m.

The Wheelbarrow Mk 9 has a two-speed transmission. The higher gear allows for speeds of up to 5kmh, while the slower gear allows for precise positioning of the vehicle.

The Wheelbarrow Mk 9 has two notable upgrades over its predecessors:the ability to move its arm to pre-set positions and a separate datachannel for additional sensor integration. Both extend the vehicle'scapabilities to suit specific missions.

From the very firstversion made from a garden wheelbarrow (hence the name) and a lawnmowerin the 1970s by Lieutenant Colonel Peter Miller for use by the BritishArmy bomb disposal teams operating in Northern Ireland, the WheelbarrowUGS has undergone many changes to become one of the mostwidely-deployed UGSes in the world.

Its predecessors such as theWheelbarrow Mark 8 II and Wheelbarrow Revolution are currently inservice with numerous armed forces, including those of the UnitedStates and Britain, and have also been deployed to assist with otheroperations such as airport security, nuclear surveillance andmaintenance, as well as hostage situations.

Launched in April,the Wheelbarrow Mk 9 is expected to join the ranks of more than 2,000UGSes currently in operation with 52 armed forces around the world.

ALSO READ IN TECHNOLOGY

AI joins the fight in national cyber defence exercise

12 Nov 2025

AI and closer collaboration among agencies and industry are taking centre stage in this year’s Critical Infrastructure Defence Exercise (CIDeX).

They built this city

01 Oct 2025

Turning vision to reality: the team behind SAFTI City clinches the Defence Technology Prize 2025 Team (Engineering) Award!

Operating over skies & seas

22 Aug 2025

This gear is designed to help a Sensor Supervisor survive emergencies in the air and at sea.