TECHNOLOGY

Green stamp of approval

01 Oct 2017

As Singapore gears up towards being more environmentally conscious, check out how the Ministry of Defence (MINDEF) and the Singapore Armed Forces (SAF) have been doing their part.

The earth is dying. That is not news - after all, it has been a recurring hot topic in recent decades.

You probably remember seeing "reuse, reduce, recycle" posters all around your school and neighbourhood. And who can forget the green frog mascot plastered over bins?

Today, we have (cheesy) saving Gaia jingles and advertisements, and more recycling bins as Singaporeans are finally getting accustomed to segregating their trash.

At the organisational-level, the SAF has been doing its part when it comes to energy saving and water conservation. From using rainwater to wash vehicles and aircraft to developing an almost net-zero energy building, the SAF is stepping up efforts in being environmentally conscious.

Camps are also starting to recycle food waste, an initiative which can generate a lot of energy if it takes off. Here's a look at some of the SAF buildings and projects which boast energy efficiency, water efficiency and ecofriendliness, among other green features.

HQ CSSCOM

Au naturel

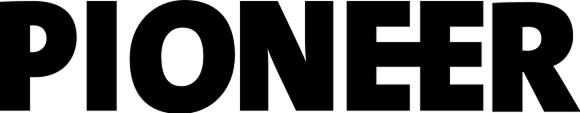

Located in Kranji Camp III, Headquarters Combat Service Support Command (HQ CSSCOM) attained the Green Mark Gold Plus award in July 2011. It obtained between 85 and 89 points (out of 100), and was certified to have at least 25 percent savings in energy consumption.

Advantageous wind flow

The bunks in HQ CSSCOM are north-south facing to take advantage of the north-south wind which is prevalent in Singapore. This reduces the need for fans and air conditioning.

Rainwater wash

Remember how Singapore's famous comic icon

Mr Kiasu used to wash his car whenever it rained (cos free mah)? Well, the SAF has picked up on this by using rainwater to wash military vehicles. A filtration system has also been installed to recycle the water used for washing, which further reduces water usage. Mr Kiasu would definitely approve.

Solar power

Natural ventilation

Other conservation efforts:

Motion-activated lights

Motion sensors in toilets reduce the use of lights, resulting in savings of 5,840kWh per year.

Water-efficient fittings

Water-efficient taps and flushing systems reduce the consumption of water by about 6.5 million litres each year, which is the volume of about two-and-a-half Olympic swimming pools.

Recycled air dryer

Hot air from the air conditioners enters the hot air vent. This hot air is then emitted through the black vent into the laundry room to dry clothes. These natural dryers are currently located at both OETI and 1st Army Maintenance Base.

New lease of life

Too many shredded documents and unused cardboard boxes? Since 2012, OETI has been working with waste management service, SembCorp Environment, to recycle common office waste by getting the latter to collect them when the bins are full. These documents will eventually be remade into recovered paper.

NSFs take lead in green initiatives

Sometimes, it just takes a few Full-time National Servicemen (NSFs) to rally a whole formation.

Private (PTE) Benjamin Mak and PTE Veshant Chettiar would know that - they were the ones who came up with the CSS Green Campaign 2017.

Launched in August and organised by the CSS NSF committee, the green campaign was an opportunity to promote environmental awareness among the CSSCOM community.

The team also invited experts to talk about issues like the importance of water conservation, climate change and global warming challenges.

Co-chair of CSS NSF Committee PTE Mak explained: "Climate change is an important issue to Singapore and it's something that the SAF is concerned about. This campaign not only helps to save money, it's also very inclusive because regardless of your rank, appointment and capability…it's something that you can contribute to."

By the time you read this, the 25-man committee will have already organised their second event on 19 Sep. In the CSS Green Project Showcase, NSFs from each CSS formation had to lead and present their green projects, share their challenges and learn from one another.

Fellow committee co-chair PTE Veshant said: "We've already seen some of the formations embarking on green initiatives like turning off the air con during work hours and lights after office hours to reduce power consumption."

Moving forward, the CSS NSF committee plans to develop a green work plan by planning at least one green-themed event a month.

Activities range from cleaning up a water body to observing World Water Day and Earth Hour.

Rainwater-collection roof

Rainwater from the roof is collected into tanks (pictured right) and used for flushing. There are currently 17 rainwater collection tanks across the naval base with a total holding capacity of 57,000 litres. With an average rainwater collection of 10 million litres (equivalent to four Olympic-size swimming pools) a year, this translates into yearly water cost savings of up to $32,000.

Innovative cooling solutions

Instead of potable water, seawater and an ice-making system are used to cool air-conditioning units in buildings within the base. As a result, the amount of potable water saved every year can fill up to 200 Olympic-size pools!

Indirect seawater cooling system

In an air-conditioning system, warm air in the room is cooled when it flows over chilled water pipes, resulting in the latter absorbing heat.

The heated water is then carried to a condenser water network for heat exchange to take place and cool it down again.

The seawater cooling system works almost the same way, except that instead of potable water, seawater is used to remove heat in the condenser network. This is done through a heat exchanger (blue system in top photo).

The heated seawater then flows back to the sea, while a fresh cold batch is pumped in to repeat the heat-removal process (black pipes in middle photo).

At the same time, chilled water in the pipes is also pumped to the air-con units in the buildings to cool the air.

There are currently 15 buildings benefitting from this plant, including office buildings, the sports complex and cookhouse.

Ice-thermal storage system

Since October 2000, the ice-thermal storage system (pictured right) has been producing ice during the off-peak period at night. The ice is then melted and used supplement part of the airconditioning load during the day.

Fun fact

Using seawater will result in the growth of barnacles and marine organisms, which choke the system and cause corrosion. To prevent this, corrosion-resistant materials like fibre-reinforced plastic pipping were selected and chemical treatments such as chlorine were added in the pumps to inhibit marine growth. A passive filter was also fitted at the wharf to remove large marine particles.

Net-zero energy building

Come January 2018, this building will be the first in the Republic of Singapore Navy to run on almost zero energy. It will be used for the storage and maintenance of both Unmanned Surface Vessels and Specialised Marine Craft.

One of the compound's main highlights is the rainwater collection ground feature. Rainwater will seep into an underground water tank, which has a holding capacity of 200,000 litres. The water will be used for testing the engines of the vessels.

Solar pipes (circle) are pipes that redirect and reflect sunlight to interior spaces. Head Infrastructure Development Branch from the Naval Plans Department Jason Chong explained: "Normally, when we do an engine test, we have to use water to cool the engine. However, using piped seawater will cause corrosion to the pipes, while potable water is wasteful and expensive, so rainwater is the best cost-saving option."

Other features of the building include solar panels and solar pipes. The former is sufficient to power all the air-conditioning units and LED lights in the building, while the latter directs natural light into the facility to reduce the need for electrical lighting.

Sun energy

Fitted in 2002, these solar panels, which number 72 in all, supply power to lighting in the Fleet Command building.

This saves about $1,000 a year on energy consumption.

Since then, several other buildings such as the Changi C2 Centre and Changi Naval Training Base's cookhouse also feature such panels, bringing the total count to about 500.

Other initiatives

From food to gas

Ever wonder what goes on in a food recycling plant? After dumping the food waste, microbes and enzymes are added to break the food down.

This generates biogas which, in turn, is converted into electricity to offset the power used at the plant.

While this is interesting and definitely energy-saving, the bulk of the effort actually begins at the source.

The food waste collected cannot be overly contaminated; things such as plastics and bones have to be separated at the point of collection.

Last November, the National Environmental Agency (NEA) started working with several SAF camps to pilot a food waste recycling project.

Food waste from the camps' cookhouses are collected daily by NEA's appointed contractor, Veolia, and driven to the recycling plant at Ulu Pandan.

The camps currently involved in this project are Kranji Camps II and III, and Maju Camp. They were chosen for their close proximity to the plant.

As with every new initiative, the challenge lies in a mindset change of consumers, said Ms Joyce Tan, who oversees the project. "To create awareness and publicity, we put up posters around the cookhouses. We even had duty officers stationed at lunch time to help educate and supervise the soldiers!" said the Ration Tech Office Manager from HQ Supply.

Ms Tan hopes that more camps will eventually be involved in the food waste project.

She added that while the food waste bin initially contained other trash like tissue and ice-cream cups, it has gotten much better. The contamination has since been reduced to about five percent.

Based on the results of this food waste project, NEA will eventually decide whether to implement this in other camps.

Reduction of aircraft wash cycle

The Republic of Singapore Air Force is also doing its part for water conservation by reducing its aircraft wash cycle from once a month to once in three months. Not only does this save manpower and time, it also cuts the usage of potable water.

Other green mark buildings

Defence Science and Technology Agency Integrated Complex

• Attained the Green Mark Platinum - the highest award for an individual building

• Green features include efficient cooling, adaptive lighting, water conservation and renewable energy

• Achieves energy savings of 35 percent and potable water savings of 70 percent

SAFRA Punggol

• First SAFRA clubhouse to be awarded the Building and Construction Authority Green Mark Platinum Award

• Green initiatives include naturally ventilated atrium and corridors, full LED lighting, solar-powered systems and use of energy-efficient air-conditioning system

• Tenants required to adopt recycling strategies to reduce overall waste

• Achieves savings of up to $30,000 a month

ALSO READ IN TECHNOLOGY

AI joins the fight in national cyber defence exercise

12 Nov 2025

AI and closer collaboration among agencies and industry are taking centre stage in this year’s Critical Infrastructure Defence Exercise (CIDeX).

They built this city

01 Oct 2025

Turning vision to reality: the team behind SAFTI City clinches the Defence Technology Prize 2025 Team (Engineering) Award!

Operating over skies & seas

22 Aug 2025

This gear is designed to help a Sensor Supervisor survive emergencies in the air and at sea.