TECHNOLOGY

Game changers of defence tech

31 May 2019

Rapid technological growth is the new norm in every sector, and the military is no exception.

Just as soldiers sharpen their skills in combat and mission planning, defence scientists and engineers flex their muscles in designing and acquiring technology to suit the military's needs.

Today, the local Defence Technology Community (DTC) is a 5,000-strong set-up that lends its engineering and systems expertise to help the Singapore Armed Forces (SAF) respond faster and make better decisions — all while driving down costs and manpower needs.

It comprises the Defence Science and Technology Agency (DSTA) and DSO National Laboratories (DSO), as well as several agencies within the Ministry of Defence (MINDEF).

Ace Team

While DSTA harnesses technology to deliver capabilities such as weapons and IT systems, DSO focuses on the Research and Development (R&D) of technological solutions. The Future Systems and Technology Directorate in MINDEF, on the other hand, is responsible for master-planning and managing the SAF's requirements.

FSTD is constantly looking for emerging technologies that can address the SAF's key challenges, said Deputy Future Systems and Technology Architect, Colonel Victor Huang. "For example, artificial intelligence, robotics, and sensor technologies are some key areas that can help to transform SAF operations.

"Besides R&D, it is important to conduct experiments together with end users, so that the final capability can best meet their needs."

PIONEER meets the local scientists and engineers who work to build up the SAF's capabilities.

Seeing further, acting faster

The SAF is realising the potential of autonomous vehicles. Unmanned systems take the first leap in the battlefield, allowing soldiers to see further and make better decisions while they stay in a safe location. These systems are also designed to be increasingly autonomous, reaping manpower savings.

Looking through walls

You've seen the movies where special forces storm an apartment, swiftly clearing rooms one by one and taking down all the bad guys.

In reality, it is a lot more complex than it seems. Even if commanders have the floor plan, it does not reveal the number of armed assailants in the quarters. And what if the layout has changed?

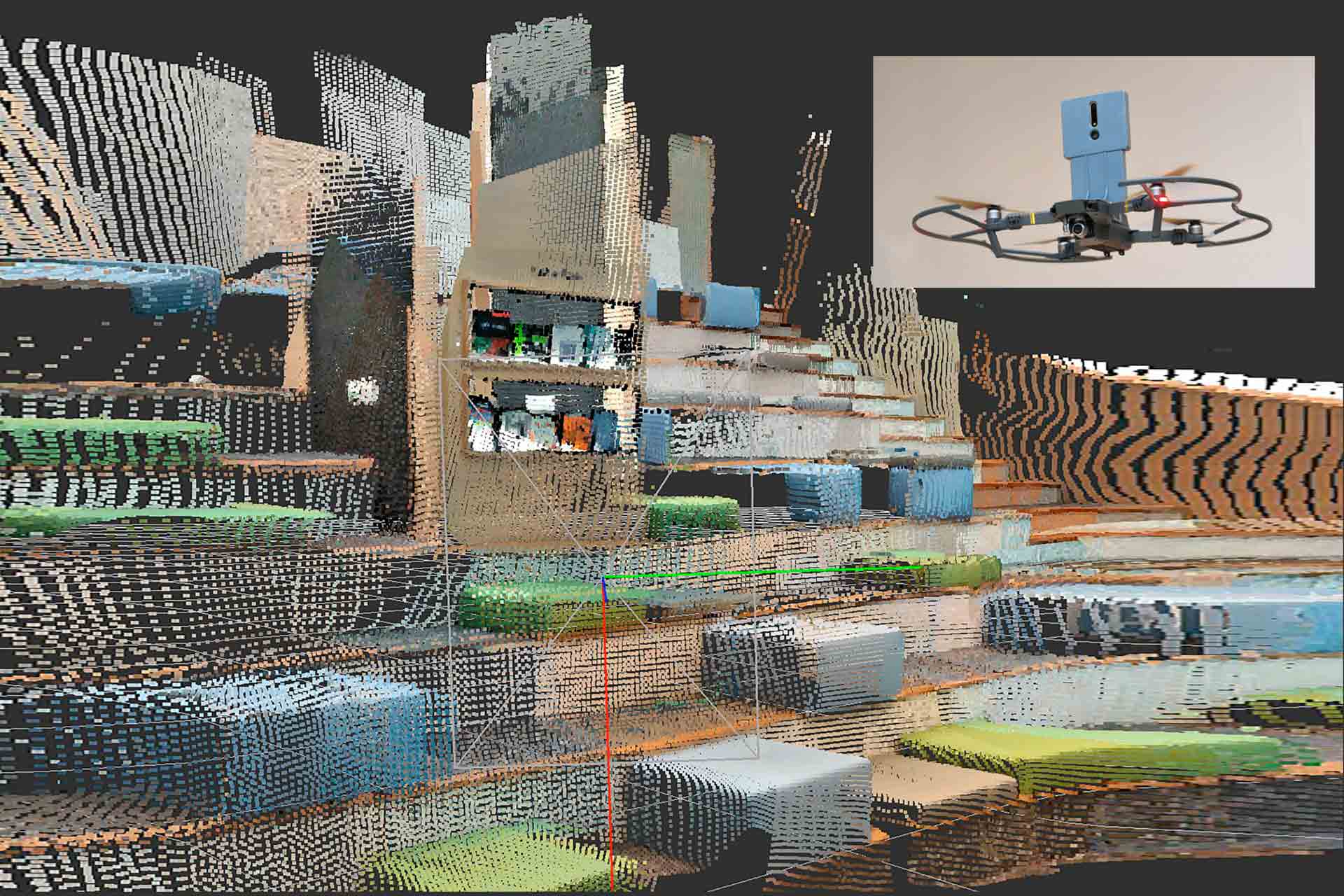

This is where indoor mapping comes in. Using just two drones, a team of DSO engineers have constructed a 3D map of a previously uncharted area in

real time.

Working simultaneously, their indoor mapping drones have successfully mapped DSO's library — around the size of a 5-room flat — in just 1min 30s.

Taking the first step

These drones can explore and navigate autonomously without any prior set-up or the use of the Global Positioning System.

This is an impressive technological leap, considering that most indoor mapping drones require operators to set up beacons in the room for the drone to locate where it is. "But this is not practical for us; we cannot expect soldiers to go into a hostile area and set up (equipment)," said flight control engineer and project lead Poh Yze Yang.

Instead, DSO's indoor drone uses a smart navigation algorithm that allows it to map in real time and track its own location based on its distance to the walls and objects it is mapping. The team's algorithm also allows multiple drones to work in tandem and contribute to the same mapping image so that they can map faster.

Information from both drones are then consolidated and sent to a command post in real time. The result is a precise 3D model of the apartment's interior, rendered in a true-to-scale grid.

"We want to use unmanned assets to mitigate risks for our soldiers, especially in urban fighting where the casualty rate can be quite high," said Mr Poh, 31.

With this remote surveillance capability, commanders can make better decisions on their next course of action and even the number of soldiers to deploy.

The drones also have a "smart command and control" mode for commanders to direct it to areas of interest when needed. For example, the drones can be instructed to inspect the corner of a room where terrorists are suspected to be hiding at.

Mapping faster

In order to improve the drone's speed and accuracy, the DSO team will enhance the system with stereo cameras — using two cameras to give the depth between objects and thus form a 3D image.

This replaced the Time of Flight sensors which the team initially used — these sensors emit infrared light in order to measure its distance from an object. While the concept worked, mapping was slower and enemy forces could detect the infrared emissions.

"We're trying to map faster because time is critical when it comes to operations, (such as) counter-terrorism missions. This upgrade brings us closer to it being applied for military use," noted Mr Poh.

The stereo camera can also be switched to use low- light sensors, should there be

a need to enter a dark room.

The project is part of a DSO initiative to get young engineers to brainstorm simple and effective solutions to complex problems, explained Mr Poh. The team is then led by senior engineers like him to explore the feasibility and cost-saving applications of these ideas.

Sea sentinel

Standing at 8m tall with its hawk-like eyes trained on the seas, the Unmanned Watch Tower (UWT) is a mighty companion to the troopers who guard against intrusions on Jurong Island.

The tower uses advanced low-light cameras to provide a wide field of view so that 24/7 surveillance can be done remotely at a command post, reducing the manpower for such operations by up to 30 per cent.

It is also equipped with smart video analytics tools for automated detection of suspicious activities in the waters. In the past, soldiers would take shifts on the watch towers and visually scan the sea using binoculars.

Designed and built by DSO, the first UWT on Jurong Island became operational last March, with another two deployed in September.

Robust detection

DSO had just a month to deliver the first tower after they signed the UWT contract in February 2018. To pull this off, a team was put together comprising members with expertise in systems engineering, human factors engineering and artificial intelligence.

Off-the-shelf sensors were not able to detect small objects in the moving waters so the team harnessed their own video analytics knowledge to do the job.

"We added 'knowledge reasoning', so the programme would look at movement patterns, the size and colour of the object and even if it's moving within certain speed limits," said Mr Tan Yuan Sin, who is the video analytics and fusion lead. With this technology, the programme can detect if a ship is sailing erratically or even if there is a swimmer in the water.

The real challenge was for the programme to achieve a high level of accuracy at night when light conditions are poor.

"At first there were a lot of false alarms so we added 'scenario learning' for it to learn what is just reflection on the water and what is likely an object of interest," explained Mr Tan, 43.

Project director Mr Lim Poh Soon, 55, recalled one of many nights when the team stayed late to conduct night trials on the UWT. One particular night fell on Valentine's Day on 14 Feb when various system errors started to emerge.

"We ironed out the issues and managed to solve them one by one until we realised it was the ground softening below the cabin," he recounted.

"By the time we were done, it was already 10.30pm. From then on, we called ourselves the Valentino team."

Strong Tower

It was apparent to the team that their system had to be resilient to facility disruptions.

To ensure 24/7 surveillance, DSO engineers installed an independent power supply so that the UWT will continue to run even when there are power outages.

However, if power is not restored within a certain period, the system will do a "graceful shutdown" to prevent overheating and preserve its functions, explained Mr Ang Thiam Leong, 49, the system engineer of the team. The system will also automatically boot up when main power is restored.

"That's the beauty of the system — you don’t need someone to come down and run it," said Mr Ang.

The UWT cabin was made to be mobile — with its retractable mast and dimensions of a standard 20-foot container — and can be easily transported for deployment at other key installations.

Its video analytics software can also be adapted for other uses. Currently, a similar smart analytics tool is also being used by the Navy to spot suspicious persons and vessels out at sea.

What the user says

In the past, we had sentries who had to stare at the ocean for long hours with little rest. With the UWT, soldiers are in the command room operating the UWT and we can plan a more efficient use of manpower. Those who are not combat-fit can also be deployed for the job.

- said 2nd Sergeant Colin Chong, Platoon Sergeant, 9th Battalion, Singapore Infantry Regiment

Better underwater

This January, the Republic of Singapore Navy (RSN) added a new tool to its suite of mine-hunting assets: the Mine Counter-Measure Autonomous Underwater Vehicle (MCM AUV).

With the ability to detect objects more accurately and stay in the water longer than its predecessor, the MCM AUV will boost the Navy’s ability to clear mines in danger zones.

"We have been working closely with the RSN to develop this suite of tools to protect Singapore's sea lines of communications," said programme manager Alvin Bui, 36, an R&D programme manager in DSTA.

Designed and developed by DSTA, the RSN, DSO and ST Engineering, the MCM AUV is Singapore’s first locally-built AUV.

Smarter detection

Compared to its predecessor, the MCM AUV has improved endurance and detection capabilities, and yet is easier to maintain and use, said Mr Bui.

"Traditionally, mine detection and classification is a laborious job. Previous AUVs needed to be recovered from the waters before its data (the sonar images captured) could be downloaded and analysed manually.

"Things are much faster with the MCM AUV: the processing of sonar images is done automatically in real time through its Automatic Detection and Classification (ADAC) system," said Mr Bui.

The operator simply inputs the area that the MCM AUV needs to scan, and the system will calculate how long the task will take. Its advanced autonomy then allows it to swim and scan by itself while the ADAC system identifies mine-like objects and classifies them by type and size.

"At the set time, the vehicle will surface to transmit the information (it has gathered). The operator, who is in a safe location, will know if the area contains any mine-like objects," said Mr Bui. Without the need for manual analysis, operators are freed up to do more important tasks.

Beyond mine-hunting

Design and development of the MCM AUV started in 2015 as an earlier R&D AUV project. Since then, the team has worked to operationalise the AUV by increasing its endurance, improving the ADAC algorithm and boosting usability. The team also improved on the crew's ability to track the AUV's endurance and health status for better situational awareness.

In addition, the team devised a cradle-like launch mechanism so that the AUV can be launched more easily and from a wider range of platforms.

The AUV can even be configured for search and rescue purposes, added Mr Bui. "We can do more peacetime missions like search and locate. The advantage of this AUV is that it has a long endurance so it can cover larger swathes of sea."

What the user says

The need for post-mission analysis has reduced significantly. Previously it was one hour of analysis to one hour of mission (scanning). Now, with the ADAC, we have significantly reduced the analysis time. With our resources freed up, we can work on other tasks.

- said Military Expert (ME) 3 Gavin Phang, AUV Lead, 194 Squadron (SQN)

Seeing more with radar

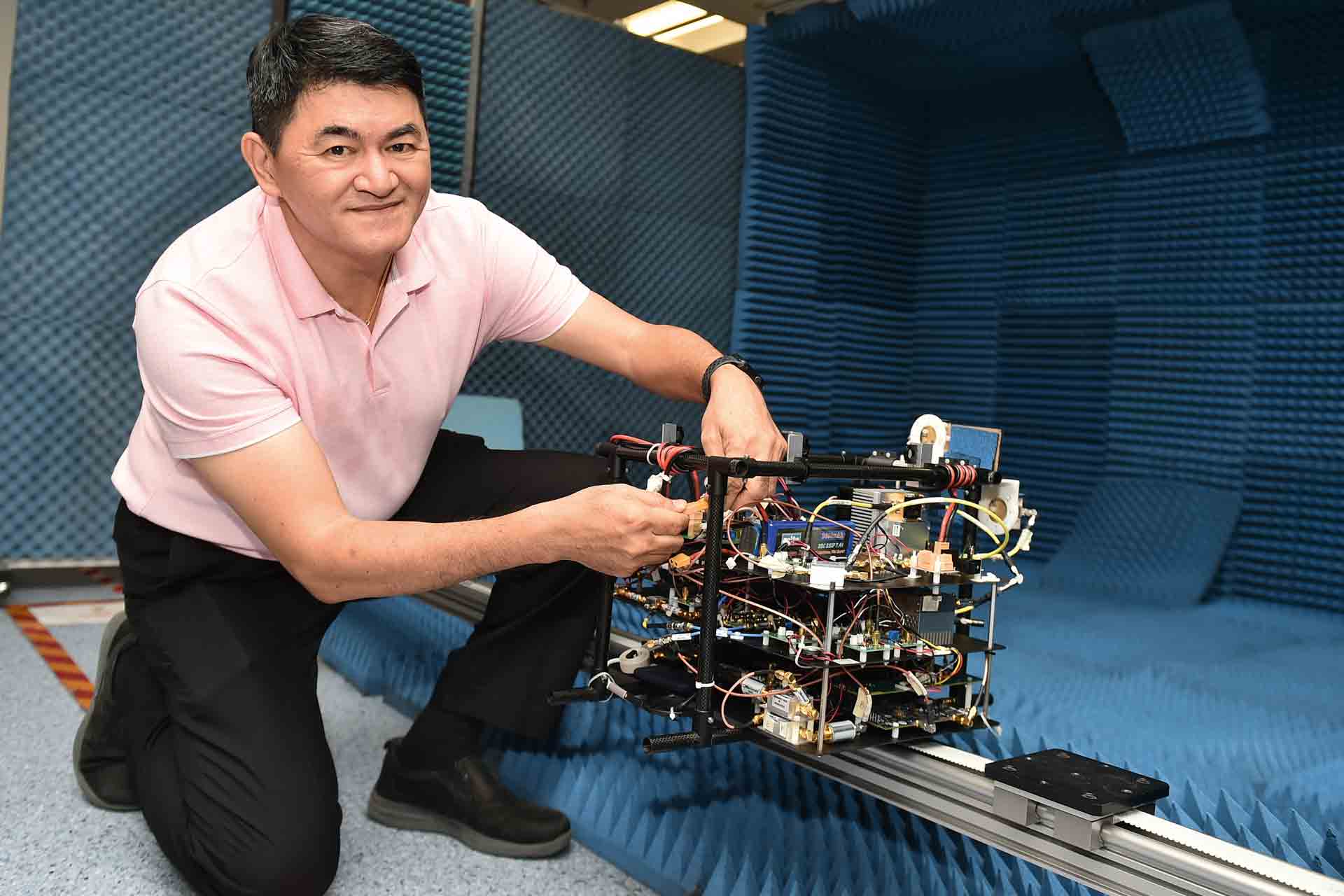

How can we capture images of the ground when there is heavy cloud cover? Cameras are limited by visibility and cannot see through clouds. However, this is not an issue for the Imaging Synthetic Aperture Radar (SAR).

The Imaging SAR emits waves that get reflected back by targets on the ground. The echoes that return are then collected for signal processing and auto-focusing to form an image.

These waves can go through cloud, rain and haze and are not dependent on light conditions — so a clear image can be obtained even in cloudy weather or at night.

Under the mentorship of DSO Principal Investigator Peter Lim, a team of students and researchers at the National University of Singapore successfully conducted their first Imaging SAR flight trial — done by building a lightweight SAR that can be mounted on a drone.

To do this, the team experimented with higher frequency waves to exploit smaller sized components. Mr Lim, 61, said: "Though the technology has existed for the past 20 years, we're always coming up with new approaches of implementing it. Operating on this high frequency band is not well-explored and we are trying this out."

With Mr Lim's trained eye, certain information can be gleaned from SAR images that is not visible on a photograph such as a walkway hidden within a building. The team will continue to improve their system processing to get crisper and sharper SAR images.

Performing better, saving costs

The SAF knows the advantage of digitalising its systems and processes. Using simulators for training can be realistic and safe, while data analytics tools can help make daily maintenance tasks more efficient. The freeing up of resources and hardware also drives down operating costs.

Virtually at sea

Mr Soh with the LMV simulator, which is surrounded by a 360-degree screen for the crew to experience immersive training.

Even as the RSN upped its capabilities with the launch of its eight new Littoral Mission Vessels (LMVs), what people might not know is that there is a "ninth LMV" in the fleet.

The RSS Daring — LMV Simulation Centre (SIMCEN) leverages technology to put the crew through challenging and realistic training in a safe environment.

Built to mimic the Integrated Command Centre (ICC) found on LMVs, the simulator allows the crew to hone their navigation, engineering and combat skills. The SIMCEN is located in Tuas Naval Base and houses two LMV simulators.

Since it opened last September, it has helped the Navy cut LMV training hours by up to 60 per cent. The centre was jointly developed by the RSN and DSTA.

Scenario-based learning

"The whole purpose of the SIMCEN is for the Navy to be able to train for scenarios that they cannot safely do out at sea," said programme manager Stanley Soh. This includes facing down other vessels, including rogue vessels, through the use of Computer-Generated Forces (CGF).

The CGF leverage artificial intelligence to make training scenarios more challenging. The scenarios are projected on a 360-degree screen that surrounds the simulator's ICC to give an immersive feeling of being in the waters.

"Through the use of technology, we are able to create realistic scenarios that give the impression that your ship is moving, even when it's not," recounted Mr Soh.

The 52-year-old added that the team is exploring the possibility of incorporating machine learning into the system to make scenarios even more challenging for the crew.

It takes a single instructor at the SIMCEN's IOC to inject different scenarios for the crew to train on.

Saving cost with VR

The implementation of Virtual Reality (VR) in the SIMCEN is one of the features that Mr Soh is proudest of.

To allow the crew to gain experience in berthing an LMV alongside a wharf, DSTA suggested to use VR technology instead of adding screens to show the ship's "distance" from the wharf.

When the Officer of the Watch puts on the VR goggles, he is able to see the distance to the wharf in 3D and advise on navigation.

Looking forward, the team will be working on doing more with simulation technology — they are keen to enhance the SIMCEN by improving its automatic assessment system and the realism of its combat scenarios.

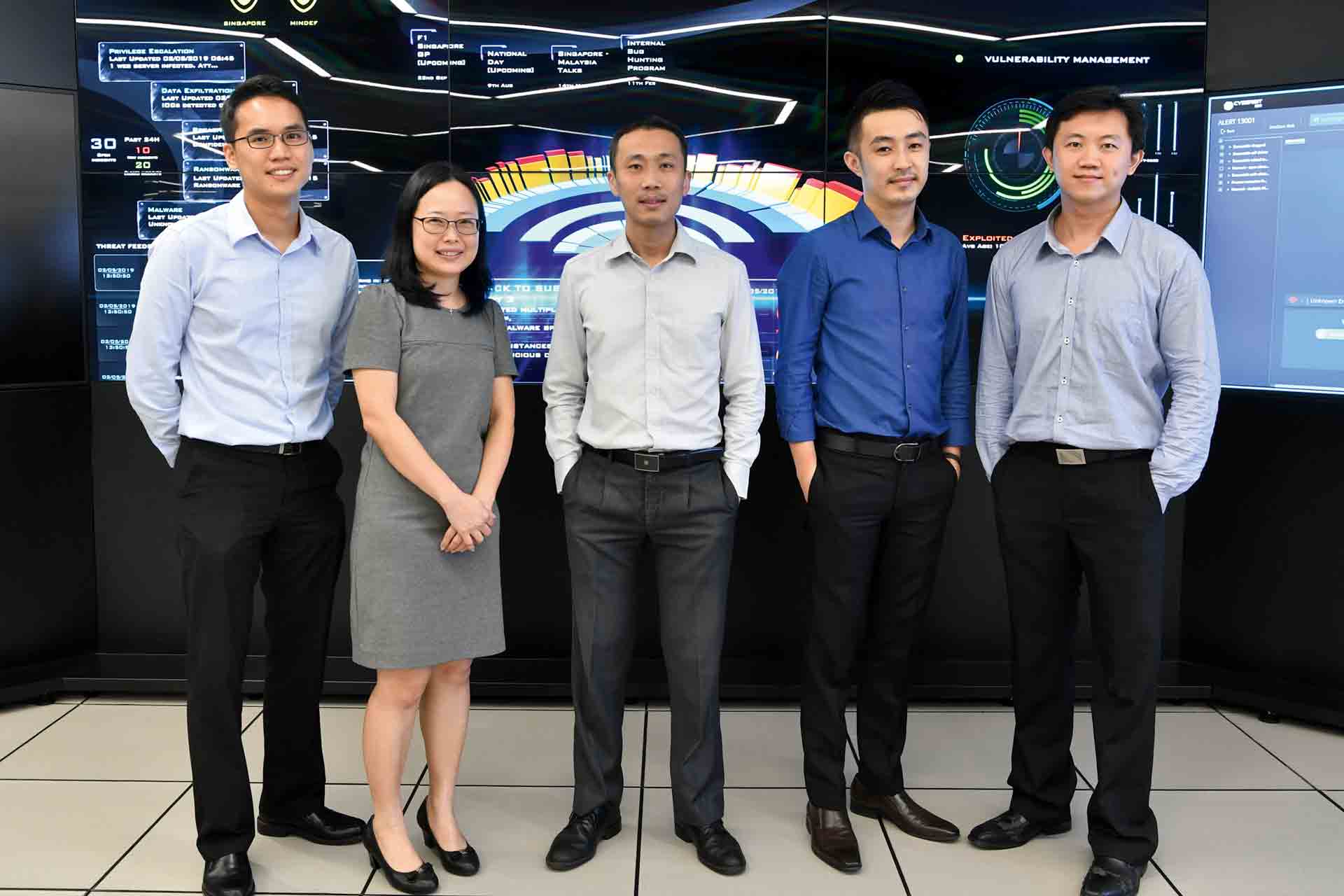

Shielding against cyber threats

In this cyber age, hackers are more sophisticated in their attacks, and system breaches are harder to detect. The role of cyber monitoring and incident response falls in part on the Cyber Security Operations Centre (SOC), which is equipped with a Security Incident and Event Management system.

To keep pace with evolving threats, a team at DSTA has come up with an in-house Cyber SOC 2.0 — a new suite of cyberthreat detection and incident management tools. This provides users with improved situational awareness of computer networks and also rapid response capabilities.

Cyber SOC 2.0 also harnesses data analytics that look for patterns beyond the norm to detect cyberthreats and prioritise alerts of these threats.

"Nowadays, threats can be so varied that we need to detect the unknown. That's why we used Artificial Intelligence and machine learning in the system to pick up advanced threats," said Senior Programme Manager Chua Boon Kwee, 44.

Cyber SOC 2.0 also incorporates an "incident response automation" feature that plays out the steps that operators should take to respond to various alerts. This improves workflow and speeds up the threat analysis process for operators.

The automation also gives operators better situational awareness. For example, it can identify the location of a malware-infected computer so that the computer can be quarantined to safeguard the rest of the system. Cyber SOC 2.0 is also designed to be modular, allowing it to quickly evolve to incorporate new innovations.

Mr Chua said: "We have to stay ahead by constantly improving our technology.

"Our engineers are always innovating new solutions and keeping track of emerging technologies that we can use."

Building a data-driven force

Those who have watched Iron Man might remember J.A.R.V.I.S, the hero's smart assistant that alerted him on his failing vital systems and which tools he should utilise.

This technology might not be far from reality as the SAF is using a suite of analytics tools that can detect system anomalies before bigger issues surface.

Developed by a team of DSTA data scientists and engineers, the Fleet anagement System (FMS) harnesses data analytics and the Internet of Things to optimise resources.

DSTA's Head Data Scientist Ho Chi Ming said: "FMS helps to optimise utilisation so that we can reduce operating cost. This is important as our fleet is becoming more complex to operate."

Since it was rolled out progressively in 2018, the system has helped to meet different operating needs of the SAF.

Longer sails for a stronger Navy

In order to sail longer at sea, the crew must be mindful of its ship's vital signs. Current monitoring systems are threshold-based and only raise an alarm if a certain value in the system crosses the threshold.

With the FMS, early detection models are able to detect system anomalies faster, even before the systems show signs of failure.

"We're using machine learning to give us pre-emptive insights so that ship commanders can plan ahead," said Mr Ho, 38.

For instance, if a diesel generator is shown to have an impending defect, the crew can swing the load away from the generator while working to check and fix it. This predictive maintenance system, currently in use on the Navy's frigates and LMVs, has helped the Navy save an estimated $500,000 in cost avoidance.

Smarter task planning

Maintaining fighter jets that return from a mission is a complex process. It can be made even more difficult if the technician's support equipment is scattered around a large air base.

The base planner's task is a complex one as he has to ensure maintenance schedules are planned well when assigning resources and manpower.

With the FMS, the base planner is able to track the assets and support equipment housed around the base, as well as monitor the health status of aircraft. This gives him better situational awareness to plan the maintenance schedules.

The FMS also helps reduce maintenance planning time with a tool that optimises task schedules based on mission priorities and needs.

Optimising resources

For the Army, the FMS helps it to better manage its large fleet of combat vehicles, spread across military camps around Singapore. With the system's resource management tool, the vehicles are grouped together in a central pool for improved awareness and planning.

"With this central pool, the Army can efficiently assign vehicles to satisfy different training needs," explained Mr Ho. This optimisation of the training fleet has also helped the Army reduce the number of active vehicles required to support training activities.

As the team continues to push for data-driven processes, its FMS engine will use machine learning to get smarter, added Mr Ho.

The benefits of harnessing data can even translate from resource management to operations, he said. "For example, we can correlate maintenance records with usage patterns to better institute preventive actions in training that could prevent defects to the asset."

What the user says

The FMS allows us to execute smart planning when coordinating daily operations. It considers various constraints such as mission priorities, manpower and competencies. With the digitalisation of current processes, we have a higher situational awareness on the health state of our aircraft to make better decisions on optimising resources.

- said ME4 Jonathan Si, Officer Commanding (OC) Aerosystems Maintenance Flight, 805 SQN. ME4 Si utilised the FMS in his previous role as Deputy OC Integrated Maintenance Flight F-16C/D.

ALSO READ IN TECHNOLOGY

AI joins the fight in national cyber defence exercise

12 Nov 2025

AI and closer collaboration among agencies and industry are taking centre stage in this year’s Critical Infrastructure Defence Exercise (CIDeX).

They built this city

01 Oct 2025

Turning vision to reality: the team behind SAFTI City clinches the Defence Technology Prize 2025 Team (Engineering) Award!

Operating over skies & seas

22 Aug 2025

This gear is designed to help a Sensor Supervisor survive emergencies in the air and at sea.