TECHNOLOGY

Innovations for a safer and more efficient operational environment

23 Jul 2024

Creative solutions and improvements from SAF personnel have significantly reduced man-hours and increased operational efficiency.

The digitisation of mobilisation resulted in a shorter waiting time for Operationally Ready National Servicemen (NSmen) and active personnel.

Repurposing commercially available magnetic polyurethane patches to develop a repair patch for firefighting and damage control use in ships.

A digital data analysis kit to monitor voltage signals in real-time for the Republic of Singapore Air Force’s (RSAF’s) F-15SG landing gear system.

These are some of the innovations by Singapore Armed Forces (SAF) personnel that were lauded at IGNITE Innovation Symposium 2024.

Held from 23 to 24 Jul, this year’s innovation symposium award ceremony saw a total of 121 individuals, teams and units from across MINDEF and the SAF being recognised for their innovations and work improvement efforts.

In particular, four units won the pinnacle Minister for Defence Award (MDA) for their outstanding achievements. Here’s a look at three of these award-winning projects.

Project ROAR by Singapore Army’s 3rd Singapore Division

What it is: A digitalisation of the mobilisation process that makes in-processing and out-processing seamless and completely paperless.

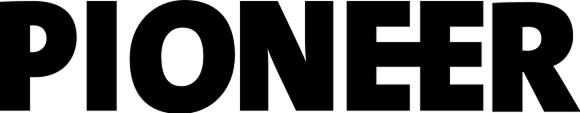

How does it help: Before Project ROAR, each serviceman had to carry a white physical mobilisation card and present it at the various stations during mobilisation to get it stamped. This led to long waiting times and a need to count the cards to tally the numbers, which would eventually be relayed to the Brigade Headquarters (HQ).

Now, servicemen can simply use their NRICs or Singpass for the entire process, eliminating the tedious task of manually counting the completion rates at each station.

In addition, the digitalisation has allowed the team to create a dashboard that provides real-time information on the mobilisation flow to the brigade headquarters, enabling them to react quickly to issues that may arise on the ground.

Savings in numbers: With registration and updates of attendance reporting now fully digitalised, this initiative has saved more than 300 man-hours per mobilisation exercise.

Feedback from NSmen on this digitalisation has been positive, said CPT Saygar.

"The new system not only reduces wait times but also provides real-time updates through a dashboard, enhancing efficiency," shared the 34-year-old Deputy Operations Officer from the 8th Singapore Armoured Brigade.

"As the digital system provides real-time data, this enables Brigade HQ to monitor the mobilisation flow and quickly respond to any issues. This system has transformed operations by saving time and reducing manpower requirements, making them more efficient and responsive."

What’s next: This template will be scaled up into the Smart Mobilisation system developed within the OneNS application from the next working year, following their trial this year.

Rapid Hull Damage Repair Patch by the RSN’s 8th Flotilla

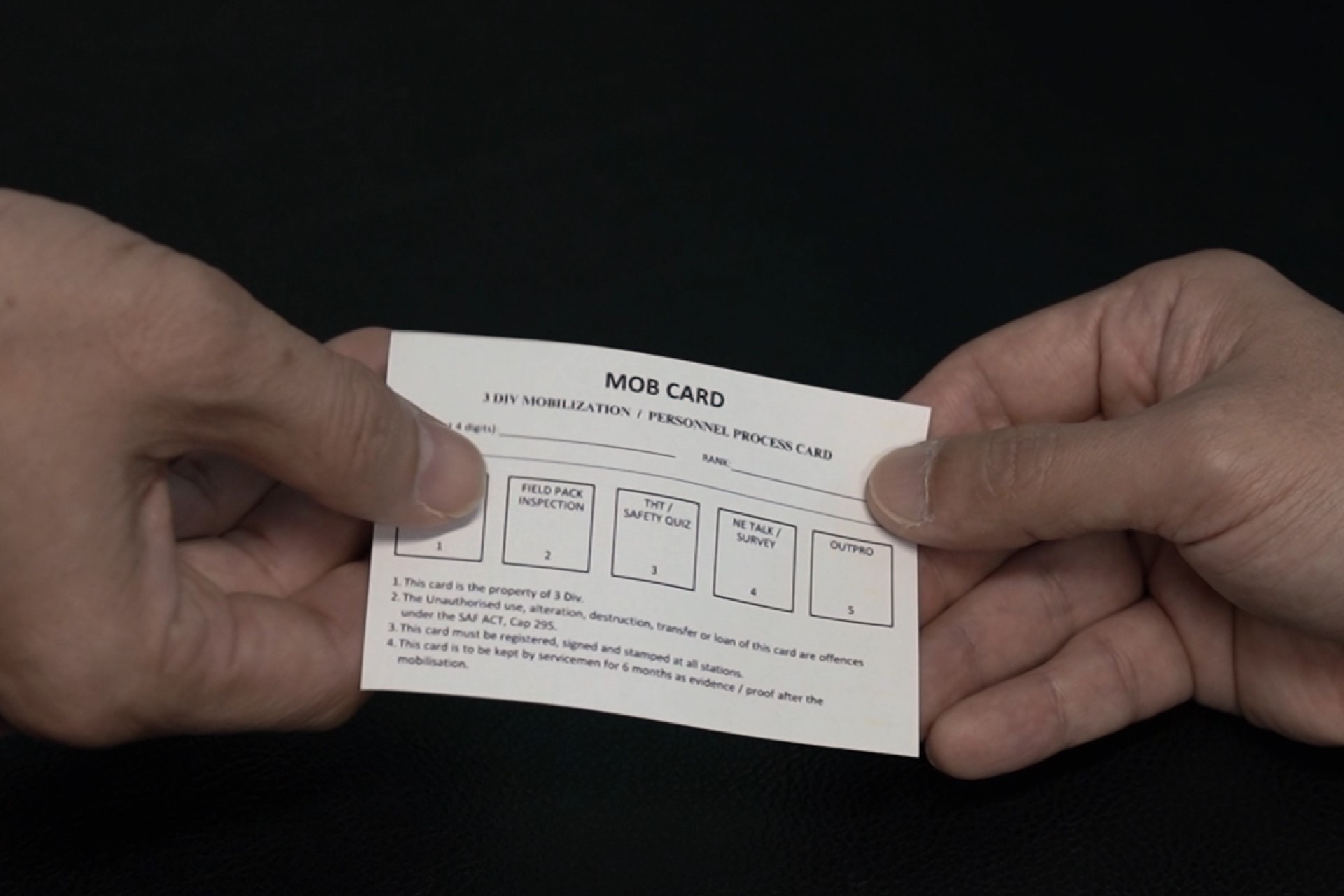

What it is: Using magnetic polyurethane sealing technology, the Rapid Hull Damage Repair Patch creates a tight seal on bulkheads or compartments to contain flooding and maintain the ship's stability. Originally used for industrial leaks, this patch has been adapted for firefighting and damage control on ships.

How does it help: Traditionally, damage control on ships required up to three personnel to manage leaks and flooding by pressing a metallic box to constantly press against the affected area. The Rapid Hull Damage Repair Patch simplifies this process by allowing just two personnel to deploy the seal and contain the flooding more efficiently.

Savings in numbers: The seal can be deployed by two personnel and one to man, thus reducing the manpower required for damage control. It also minimises damage to the affected area and allows crew members to efficiently contain leaks or floods in a shorter time.

Even though they faced challenges during the development of the magnetic patch, seeing its impact and success makes it all worthwhile, said ME3 Ngo.

The 41-year-old is the Chief of Electrical Control Systems from 8th Flotilla.

“The new patch allows our crew to contain leaks or floods more efficiently, ensuring the ship's stability with less manpower. The innovative use of magnetic sealing technology has streamlined our damage control processes, making it quicker and safer to address hull breaches and flooding.”

What’s next: The Rapid Hull Damage Repair Patch is aimed to be implemented by this year for ships across the Republic of Singapore Navy (RSN).

Landing Gear Digital Data Analysis Kit by the RSAF’s 7 Air Engineering and Logistics Group

What it is: A voltage recorder which allows the crew to do real-time monitoring of the voltage signals of the F-15SG landing gear system from a safe distance.

How does it help: Previously, the crew would use a multimeter which required them to position themselves close to a moving landing gear strut during the troubleshooting process. At times, multiple swings have to be conducted to ensure that the defect exists in order to troubleshoot it, making it time-consuming.

With the new digital analysis kit, the crew just needs to just hook the data logger to the plane and capture all the data in one swing, at a safe distance from the plane.

Savings in numbers: This kit has resulted in a 50 per cent manpower reduction and an 80 per cent in overall man hours needed for troubleshooting of a landing gear defect. It has also eliminated the dangers of a physical analysis and the need to conduct multiple landing gear swings.

"This kit has significantly improved both safety and efficiency. The ability to monitor voltage signals from a safe distance has not only made the process quicker but also greatly enhanced the safety of our personnel during maintenance operations,” said ME1 Ng, 24.

The Qualified Senior Technician from 817 Squadron(SQN) also felt that the support for an innovation culture within his squadron has been very strong.

"Our management has been encouraging and provided valuable feedback throughout the project. My teammates were also dedicated and hardworking, which made this project a success."

What’s next: This team aims to share the kit with their sister squadrons and potentially, the RSAF’s overseas training detachments.

ALSO READ IN TECHNOLOGY

AI joins the fight in national cyber defence exercise

12 Nov 2025

AI and closer collaboration among agencies and industry are taking centre stage in this year’s Critical Infrastructure Defence Exercise (CIDeX).

They built this city

01 Oct 2025

Turning vision to reality: the team behind SAFTI City clinches the Defence Technology Prize 2025 Team (Engineering) Award!

Operating over skies & seas

22 Aug 2025

This gear is designed to help a Sensor Supervisor survive emergencies in the air and at sea.